| “This site contains affiliate links for which OEMDTC may be compensated” |

March 1, 2018 NHTSA CAMPAIGN NUMBER: 18V140000

Chafing Brake Hose may Cause Brake Fluid Leak

A brake fluid leak can lengthen the distance needed to stop the vehicle, increasing the risk of a crash.

NHTSA Campaign Number: 18V140

Manufacturer Jaguar Land Rover North America, LLC

Components SERVICE BRAKES, HYDRAULIC

Potential Number of Units Affected 41

Summary

Jaguar Land Rover North America, LLC (Jaguar) is recalling certain 2018 Jaguar E-Pace vehicles. The brackets that secure the front brake hoses may not have been installed properly, allowing the front brake hoses to contact the tires, possibly resulting in a brake fluid leak.

Remedy

Jaguar will notify owners, and dealers will inspect the front brake hose brackets, replacing any that do not provide sufficient clearance, free of charge. The recall began on April 16, 2018. Owners may contact Jaguar customer service at 1-800-452-4827. Jaguar’s number for this recall is H074.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Jaguar has a Recall

| SAFETY RECALL H074 (NHTSA 18V140): BRAKE HOSE BRACKET | SERVICE BULLETIN |

| 21-MAR-18 | NO.: 7-147USA | SEC.: RECALL | MKT.: USA |

Jaguar Land Rover North America, LLC has informed the National Highway Traffic Safety Administration (NHTSA) of its intent to perform a voluntary Safety Recall on certain 2018 model year Jaguar E-PACE vehicles imported into the United States market. Information relating to this Recall will be posted on the National Highway Traffic Safety Administration website.

United States Federal regulations require that retailers must be notified within a reasonable time after the manufacturer decides that a defect that relates to motor vehicle safety or a noncompliance exists.

United States Federal law requires retailers to complete any outstanding safety Recall service before a new vehicle is delivered to the buyer or lessee. Violation of this requirement by a retailer could result in a civil penalty of up to $21,000.00 per vehicle.

This Recall Service Bulletin serves as notification to all Jaguar retailers in the United States and Federalized Territories that any affected new vehicles may not be sold and delivered for customer use until the Recall repair is completed.

THIS BULLETIN UPDATES 7-146USA

DESCRIPTION OF ISSUE

An issue has been identified on a limited number of vehicles within the listed Affected Vehicle Range with the assembly of the front left and right brake flexi hose brackets. The brake hose brackets were subject to unauthorized plant manufacturing operations. This unauthorized operation has taken the bracket position away from design specification.

AFFECTED VEHICLE RANGE

E-PACE (X540)

Model Year: …………….. 2018

VIN: …………………………… SADFL2FX9J1Z01546-SADFM2GX9J1Z06323

A total of 41 vehicles are potentially involved in the USA and Federalized Territories. Visit the Jaguar Business Network (JBN) website for a list of affected unsold (as of 15 March 2018) vehicles.

EFFECT ON VEHICLE OPERATION

Vehicles in this condition may not meet design specification clearance requirements between the front wheel and hose and in certain scenarios may lead to the brake flexi hose coming into contact with the front tires, leading to chafing and ultimately a loss of brake fluid.

Brake fluid loss will illuminate a red warning triangle on the instrument cluster instructing the driver to seek qualified assistance. If sufficient brake fluid leaks out, this will ultimately result in extended brake pedal travel combined with reduced braking performance in the corresponding brake circuit and vehicle stopping distances will increase.

Loss of one braking circuit could compromise vehicle stability and significantly increase the risk of an accident.

SERVICE PROGRAM / REWORK ACTION

Owners will be notified by mail and instructed to take their vehicle to an authorized Jaguar retailer who will inspect the brake flexi hose bracket. If the clearance is not to the required specification, the technician will replace either one or both of the front brake flexi hose brackets. There will be no charge to owners for this action.

OWNER NOTIFICATION

Owner notification is expected to occur on or before 23 April 2018.

ACTION TO BE TAKEN

Use the Jaguar Land Rover claims submission system to ensure that the vehicle is affected by this Program prior to undertaking any rework action.

Retailers are required to HOLD affected new vehicles that are within your control and refrain from releasing the vehicles for new vehicle sale pending completion of the rework action. Affected vehicles already in the hands of customers should be updated at the next available opportunity.

Jaguar Land Rover North America recommends that affected sales demonstrator and loaner vehicles are repaired before use and that used vehicles are repaired before sale. Retailers who choose to proceed against this recommendation, where legally permitted, must clearly and conspicuously disclose the open recall to the applicable customers. Refer to Technical Bulletin H074NAS, SAFETY RECALL: Brake Hose Bracket, for detailed repair instructions.

PARTS

NOTE: order only the expected percentage demand of parts identified.

| DESCRIPTION | PART NO. / SUNDRY CODE | QTY. / VALUE | EXPECTED PERCENTAGE DEMAND |

|---|---|---|---|

| Bracket – Brake hose support – Right | J9C9321 | 1 | 60 |

| Bracket – Brake hose support – Left | J9C9322 | 1 | 60 |

TOOLS

Refer to the Technical Bulletin referenced above for any required special tools.

WARRANTY

NOTE: use the Jaguar Land Rover claims submission system to ensure that a vehicle is affected by this program prior to undertaking any rework action.

At the time of confirming a booking for vehicle repair, ensure that all outstanding Recall and Service Actions are identified to ensure the correct parts are available and adequate workshop time is allocated for repairs to be completed in one visit.

Warranty claims must be submitted quoting the Program Code together with the relevant Option Code. The SRO and parts information listed have been included for information only. The Option Code(s) that allows for the drive in/drive out allowance may only be claimed if the vehicle is brought into the workshop for this action alone to be undertaken.

Repair procedures are under constant review and therefore times / prices are subject to change; those quoted here must be taken as guidance only. Refer to the Jaguar Land Rover claims submission system to obtain the latest repair time.

Warranty claims must be submitted for payment within 30 calendar days of completion of the repair.

| PROGRAM CODE | OPTION CODE | DESCRIPTION | SRO | TIME (HOURS) | PARTS / SUNDRY CODE* | QTY. / VALUE* |

|---|---|---|---|---|---|---|

| H074 | A | Inspect the bracket, measure the clearance, release vehicle if clearance is less than the maximum allowance | 05.10.20 | 0.2 | – | – |

| H074 | B | Inspect the bracket, measure the clearance, release vehicle if clearance is less than the maximum allowance

Drive in/drive out |

05.10.20

10.10.10 |

0.2

0.2 |

–

– |

–

– |

| H074 | C | Inspect the bracket, measure the clearance, replace the brake hose bracket – Single – Right bracket | 70.91.60 | 0.3 | J9C9321 | 1 |

| H074 | D | Inspect the bracket, measure the clearance, replace the brake hose bracket – Single – Right bracket

Drive in/drive out |

70.91.60

10.10.10 |

0.3

0.2 |

J9C9321

– |

1

– |

| H074 | E | Inspect the bracket, measure the clearance, replace the brake hose bracket – Single – Left bracket | 70.91.60 | 0.3 | J9C9322 | 1 |

| H074 | F | Inspect the bracket, measure the clearance, replace the brake hose bracket – Single – Left bracket

Drive in/drive out |

70.91.60

10.10.10 |

0.3

0.2 |

J9C9322

– |

1

– |

| H074 | G | Inspect the bracket, measure the clearance, replace the brake hose brackets – Pair | 70.91.61 | 0.4 | J9C9321

J9C9322 |

1

1 |

| H074 | H | Inspect the bracket, measure the clearance, replace the brake hose brackets – Pair Drive in/drive out | 70.91.61

10.10.10 |

0.4

0.2 |

J9C9321

J9C9322

– |

1

1

– |

Normal Warranty policies and procedures apply.

TECHNICAL Q & A: SAFETY RECALL H074

Main Message: The front brake hose brackets were subject to unauthorized plant manufacturing operations. This unauthorized operation has taken the bracket position away from design specification.

Vehicles in this condition may not meet design specification clearance requirements between the front wheel and hose and in certain scenarios may lead to the brake flexi hose coming into contact with the front tires, leading to chafing and ultimately a loss of brake fluid.

| Q1 | Who do I contact if a member of the press contacts me about this recall? | ||

| A | Please ensure Press enquiries are referred to the Jaguar Land Rover North America Press Office to the attention of:.

|

||

| Q2 | Why is Jaguar Land Rover recalling certain Jaguar vehicles? | ||

| A | These vehicles are being recalled because this defect can lead to extended stopping distances. | ||

| Q3 | Can you tell me more about what is wrong with the vehicles? | ||

| A | Brake fluid loss will illuminate a red warning triangle on the Instrument Cluster (IC) instructing the driver to seek qualified assistance. If sufficient brake fluid leaks out, this will ultimately result in extended brake pedal travel combined with reduced braking performance in the corresponding brake circuit and vehicle stopping distances will increase. | ||

| Q4 | How would the customer become aware of potentially having this concern? | ||

| A | Brake fluid loss will illuminate a red warning triangle on the IC. Further, drivers may notice extended brake pedal travel. | ||

| Q5 | Does this concern affect vehicle safety? | ||

| A | Jaguar Land Rover is conducting this as this as a safety Recall. | ||

| Q6 | Has Jaguar Land Rover Limited received many complaints? | ||

| A | Jaguar Land Rover has received a number of retailer/authorized repairer reports related to this issue. | ||

| Q7 | Have there been any accidents or injuries? | ||

| A | Jaguar Land Rover is not aware of any accidents or injuries which have been attributed to this issue. | ||

| Q8 | How was the condition discovered? | ||

| A | The condition was highlighted through market reports. | ||

| Q9 | How long has Jaguar Land Rover known about this problem? | ||

| A | This issue started to be investigated in December 2017. | ||

| Q10 | Is the defect leading you to any concerns regarding the reliability of a system, which is supposed to be designed and engineered for the passengers’ safety? What type of measures are you planning to take? | ||

| A | We have no concerns with the overall reliability of the vehicle. Jaguar Land Rover carefully monitors field data to ensure that any matters relating to safety and compliance are rigorously investigated. | ||

| Q11 | What has Jaguar Land Rover done in production? | ||

| A | The bracket position is now assured during vehicle assembly. | ||

| Q12 | What will an authorized Jaguar retailers do to the vehicles? | ||

| A | Authorized Jaguar retailers will inspect and, if necessary, replace the front left and right brake hose brackets. | ||

| Q13 | Which vehicles are affected by this recall? | ||

| A | Jaguar E-PACE vehicles manufactured between 5 January 2018 and 9 January 2018. | ||

| Q14 | Are other Jaguar Land Rover models affected by these actions? | ||

| A | No other models, other than those listed on this document, are known to be affected by this condition. | ||

| Q15 | Are parts available to rework vehicles? | ||

| A | Yes, the necessary parts are available for authorized Jaguar retailers to conduct this repair. | ||

| Q16 | How much will the recall cost Jaguar Land Rover? | ||

| A | Cost was not a factor in deciding to recall these vehicles. | ||

| Q17 | How do I know if my Jaguar vehicle is affected? | ||

| A | All owners of potentially affected vehicles will shortly receive a letter inviting them to contact an authorized Jaguar retailer for the work to be carried out. | ||

| Q18 | How long does it take for the vehicle to be inspected and repaired? | ||

| A | The work will be carried out as quickly and efficiently as possible in order to minimize inconvenience to customers and is expected to take no longer than one (1) hour. Due to retailer schedules, vehicles may be required for longer. | ||

| Q19 | Can I continue to drive my Jaguar vehicle safely until it has been recalled? | ||

| A | Customers are advised to contact an authorized Jaguar retailer should they have any concerns regarding their vehicles. |

H074NAS1

TECHNICAL BULLETIN

21 MAR 2018

INFORMATION

SECTION:

206-03: Front Disc Brake

SUBJECT/CONCERN:

SAFETY RECALL: Brake Hose Bracket

AFFECTED VEHICLE RANGE:

| MODEL: | MODEL YEAR: | VIN: | ASSEMBLY PLANT: |

|---|---|---|---|

| E-PACE (X540) | 2018 | Z01546-Z06323 | Graz (Austria) |

MARKETS:

NORTH AMERICA

CONDITION SUMMARY:

SITUATION:

An issue has been identified on certain vehicles within the listed Affected Vehicle Range with the assembly of the front left and right brake hose brackets. The brake hose brackets were subject to unauthorized plant manufacturing operations. This unauthorized operation has taken the bracket position away from design specification.

Vehicles in this condition may not meet design specification clearance requirements between the front wheel or tire and the brake hose. In certain scenarios this may lead to the brake hose coming into contact with the front wheel or tire, leading to abrasion and ultimately a loss of brake fluid. Brake fluid loss will illuminate a red warning triangle on the Instrument Cluster (IC) instructing the driver to seek qualified assistance. If sufficient brake fluid leaks out, this will ultimately result in extended brake pedal travel combined with reduced braking performance in the corresponding brake circuit and vehicle stopping distances will increase.

Loss of one braking circuit could compromise vehicle stability and significantly increase the risk of an accident.

ACTION:

Retailers are required to HOLD affected new vehicles that are within your control and refrain from releasing the vehicles for new vehicle sale pending completion of the Workshop Procedure detailed in this Technical Bulletin. Unsold vehicles should have this performed as part of the Pre-Delivery Inspection (PDI) process but must have it completed prior to vehicle handover to the customer.

Affected vehicles already in the hands of customers should be updated at the next available opportunity.

PARTS:

| NOTE: |

| Order only the expected percentage demand of parts identified. |

| DESCRIPTION | PART NO./SUNDRY CODE | QTY./VALUE | EXPECTED PERCENTAGE DEMAND |

|---|---|---|---|

| Bracket – Brake hose support Right | J9C9321 | 1 | 60 |

| Bracket – Brake hose support – Left | J9C9322 | 1 | 60 |

SPECIAL TOOLS:

Refer to TOPIx Workshop Manual/Workshop Procedure for any required special tools.

WARRANTY:

| NOTE: |

| Use the Jaguar Land Rover claims submission system to make sure that a vehicle is affected by this program prior to undertaking any rework action. |

At the time of confirming a booking for vehicle repair, make sure that all outstanding Recall and Service Actions are identified to ensure the correct parts are available and adequate workshop time is allocated for repairs to be completed at one visit.

Warranty claims must be submitted quoting the Program Code and the relevant Option Code; this will result in payment of the stated time. The SRO and parts information is included for information only. The Option Code(s) that allows for the drive in/drive out allowance may only be claimed if the vehicle is brought back into the workshop for this action alone to be undertaken.

Repair procedures are under constant review and therefore times / prices are subject to change; those quoted here must be taken as guidance only. Use the Jaguar Land Rover claims submission system to obtain the latest repair time.

Warranty claims must be submitted or payment within 30 calendar days of completion of the repair.

| PROGRAM CODE | OPTION CODE | DESCRIPTION | SRO | TIME (HOURS) | PARTS/SUNDRY CODE | QTY./VALUE |

|---|---|---|---|---|---|---|

| H074 | A | Inspect the bracket, measure the clearance, release vehicle if clearance is less than the maximum allowance | 05.10.20 | 0.2 | – | – |

| H074 | B | Inspect the bracket, measure the clearance, release vehicle if clearance is less than the maximum allowance

Drive in/drive out |

05.10.20

10.10.10 |

0.2

0.2 |

– |

– |

| H074 | C | Inspect the bracket, measure the clearance, replace the brake hose bracket – Single – Right bracket | 70.91.60 | 0.3 | J9C9321 | 1 |

| H074 | D | Inspect the bracket, measure the clearance, replace the brake hose bracket – Single – Right bracket

Drive in/drive out |

70.91.60

10.10.10 |

0.3

0.2 |

J9C9321

– |

1

– |

| H074 | E | Inspect the bracket, measure the clearance, replace the brake hose bracket – Single – Left bracket | 70.91.60 | 0.3 | J9C9322 | 1 |

| H074 | F | Inspect the bracket, measure the clearance, replace the brake hose bracket – Single – Left bracket

Drive in/drive out |

70.91.60

10.10.10 |

0.3

0.2 |

J9C9322

– |

1

– |

| H074 | G | Inspect the bracket, measure the clearance, replace the brake hose brackets – Pair | 70.91.61 | 0.4 | J9C9321 J9C9322 | 1 1 |

| H074 | H | Inspect the bracket, measure the clearance, replace the brake hose brackets – Pair

Drive in/drive out |

70.91.61

10.10.10 |

0.4

0.2 |

J9C9321

J9C9322 – |

1

1 – |

Normal Warranty policies and procedures apply.

WORKSHOP PROCEDURE ‘A’ – VEHICLES WITH 18″ WHEELS ONLY:

| NOTES: |

|

1

Raise the vehicle on a ramp.

2

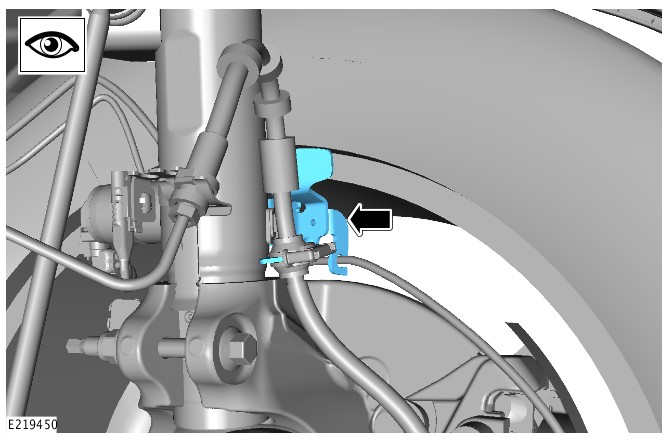

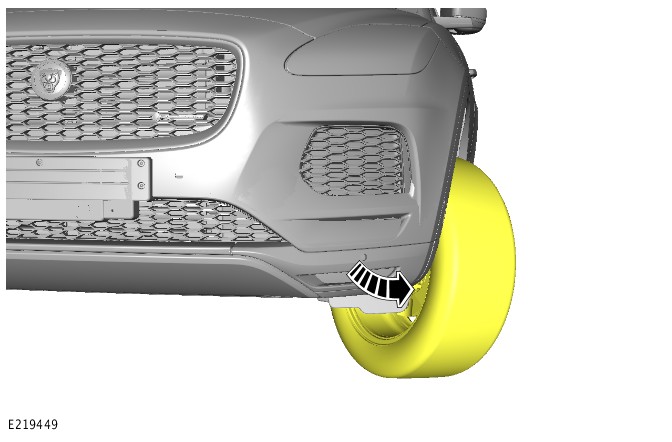

Turn the wheel and tire assembly as shown.

Turn the wheel and tire assembly as shown.

3

Locate the front left brake hose support bracket.

4

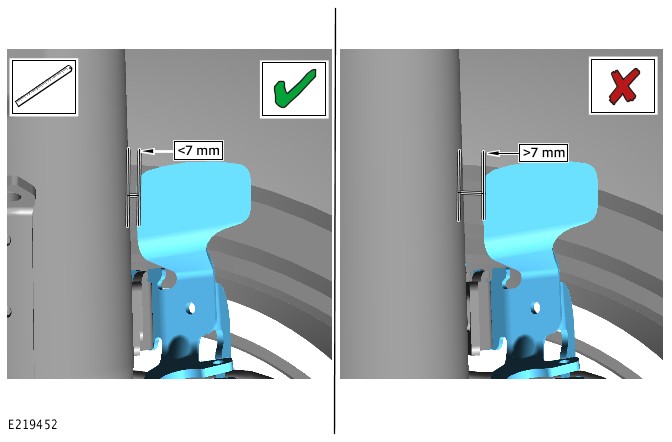

Measure and record the gap between the brake hose support bracket and the shock absorber.

5

Repeat Steps 1-4 to the other side of the vehicle.

- If the gap between the brake hose support bracket and the shock absorber is 7 mm or less (✓) on both sides of the vehicle, no repair is necessary. go to Step 10.

- If the gap between the brake hose support bracket and the shock absorber is more than 7 mm (✕) on either side of the vehicle, go to Step 6.

6

Remove the wheel and tire assembly (see TOPIx Workshop Manual section 204-04: Removal and Installation – Wheels and Tires – Wheel and Tire).

7

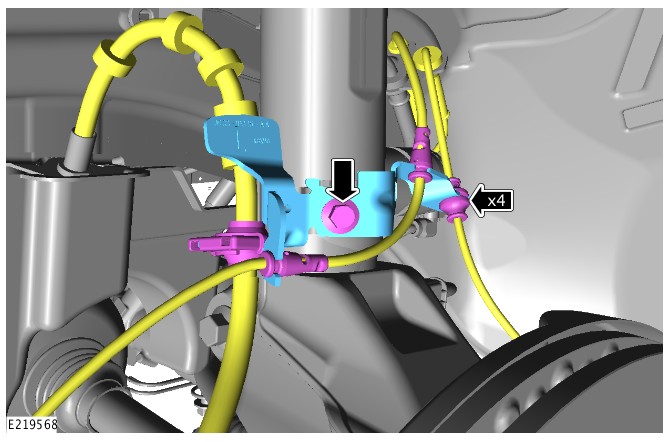

| CAUTION: |

| Following installation, a visual inspection must be completed to make sure the brake pipe(s) are routed and secured correctly. The brake pipe(s) must not touch the body or surrounding components. |

| NOTE: |

| Make sure the gap between the brake hose support bracket and the shock absorber is correct after installing the new brake hose support bracket. |

Replace the brake hose support bracket.

- Torque: 28 Nm

8

Install the wheel and tire assembly (see TOPIx Workshop Manual section 204-04: Removal and Installation – Wheels and Tires – Wheel and Tire).

9

Repeat Steps 6-8 on the other side of the vehicle if required.

10

Release the vehicle.

WORKSHOP PROCEDURE ‘B’ – VEHICLES WITHOUT 18″ WHEELS ONLY:

| NOTES: |

|

1

Raise the vehicle on a ramp.

2

Turn the wheel and tire assembly as shown.

3

Locate the front left brake hose support bracket.

4

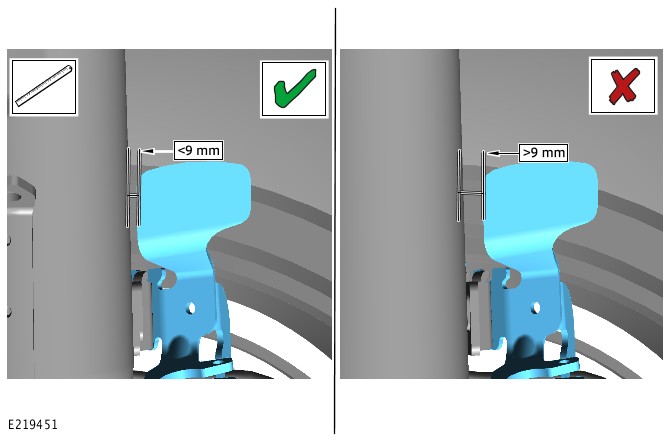

Measure and record the gap between the brake hose support bracket and the shock absorber.

5

Repeat Steps 1-4 to the other side of the vehicle.

- If the gap between the brake hose support bracket and the shock absorber is 9 mm or less (✓) on both sides of the vehicle, go to Step 10.

- If the gap between the brake hose support bracket and the shock absorber is more than 9 mm (✕) on either side of the vehicle, go to Step 6.

6

Remove the wheel and tire assembly (see TOPIx Workshop Manual section 204-04: Removal and Installation – Wheels and Tires – Wheel and Tire).

7

| CAUTION: |

| Following installation, a visual inspection must be completed to make sure the brake pipe(s) are routed and secured correctly. The brake pipe(s) must not touch the body or surrounding components. |

| NOTE: |

| Make sure the gap between the brake hose support bracket and the shock absorber is correct after installing the new brake hose support bracket. |

Replace the brake hose support bracket.

- Torque: 28 Nm

8

Install the wheel and tire assembly (see TOPIx Workshop Manual section 204-04: Removal and Installation – Wheels and Tires – Wheel and Tire).

9

Repeat Steps 6-8 on the other side of the vehicle if required.

10

Release the vehicle.

1 Affected Product

Vehicle

| MAKE | MODEL | YEAR |

| JAGUAR | E-PACE | 2018 |

10 Associated Documents

Defect Notice 573 Report

RCLRPT-18V140-9092.pdf 216.16KB

Loading...

Loading...

Recall Acknowledgement

RCAK-18V140-6898.pdf 245.846KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-18V140-8069.pdf 808.344KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)- 15-MAR-18 – NOTIFICATION OF SAFETY RECALL H074 (NHTSA 18V140)

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)- 21-MAR-18 – SAFETY RECALL H074 (NHTSA 18V140): BRAKE HOSE BRACKET

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-18V140-7779.pdf 381.287KB

Loading...

Loading...

Recall Quarterly Report #1, 2018-2

RCLQRT-18V140-6812.PDF 214.528KB

Loading...

Loading...

Recall Quarterly Report #2, 2018-3

RCLQRT-18V140-7583.PDF 211.245KB

Loading...

Loading...

Recall Quarterly Report #3, 2018-4

RCLQRT-18V140-2004.PDF 211.337KB

Loading...

Loading...

Recall Quarterly Report #4, 2019-1

RCLQRT-18V140-1706.PDF 211.442KB

Loading...

Loading...

Recalls Documents

https://www-odi.nhtsa.dot.gov/acms/cs/documentList.xhtml?docId=18V140&docType=RCL

- Provides an extra margin of safety in extreme braking conditions

- Mix of polyglycol ethers ensures hot brake-system operation will not create dangerous vapor

- Excellent for ABS, disc and drum brake systems

- Delivers braking power when needed by avoiding a spongy pedal

- Both wet and dry boiling points exceed the minimum government standards

- Premium brake and hydraulic clutch fluid that protects internal components from corrosion under normal use

- High boiling point to minimize brake fluid boiling and vapor lock

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- High compatibility. Use with or direct replacement for DOT 3, DOT 4, and DOT 5. 1

- Extended Service Interval (ESI): Lasts 100% longer than DOT 3, 50% longer than DOT 4, and 10% longer than DOT 5. 1

- Exceeds all DOT 3, DOT 4, and DOT 5. 1 standards

- Wet boiling point ~ 365 DegreeF/Viscosity at -40 DegreeC ~ 685mm2/s

- Standard brake fluid has a recommended change interval of 2 years. The recommended change interval for Bosch ESI6 is 3 years.

- The 336⁰F wet boil point and 521⁰F dry boil point exceeds common characteristics for DOT 4 brake fluids

- Provides corrosion protection in brake components

- Matches needs of all DOT 4 manufacturer recommendations

- Compatible with all DOT 3 and DOT 4 applications

- Minimal decrease of boiling point due to excellent water locking properties

- Non-foaming when filling and bleeding the brake system

- Excellent corrosion protection due to selected additives

- High safety tolerance against steam bubbles

- Makes brake fluid changing intervals of up to 3 years possible

- Synthetic quality brake fluid

- Contains special ingredients to guard against vapor lock and moisture absorption

- Exceeds requirements for both DOT 3 and DOT 4 brake fluids

- Specially formulated for DOT 4 brake fluid applications

- Designed for use in disc, drum and ABS brake systems

- Helps provide protection against brake failure from vapor lock

- Helps prevent corrosion in brake system

- Works with all brake system requiring DOT 3 fluids

- Exceeds federal motor vehicle safety standard No. 116

- Meets SAE spec. J1703.

- Extremely high wet and dry boiling points

- Miscible and compatible with high-quality synthetic brake fluids

- Assures a high degree of lubricating action on all moving components in the hydraulic brake circuit

- Outstanding protection against the formation of steam bubbles

- Excellent viscosity/temperature properties

Last update on 2024-03-19 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.