| “This site contains affiliate links for which OEMDTC may be compensated” |

TECHNICAL BULLETIN

JTB00257NAS3

06 MAR 2014

SECTION: 204-04

Wheel/Tire Balancing and Optimization

AFFECTED VEHICLE RANGE:

| XJ Range (X351) Model Year: 2010 Onwards VIN: V00047 Onwards |

| XK Range (X150) Model Year: 2007 Onwards VIN: B00379 Onwards |

| XF (X250) Model Year: 2009 Onwards VIN: R00019 Onwards |

| F-TYPE (X152) Model Year: 2014 Onwards VIN: K00317 Onwards |

MARKETS:

NAS

CONDITION SUMMARY:

Situation: The steering wheel may exhibit a vibration / shimmy while driving.

Cause: This may be caused by a road wheel/tire assembly imbalance and/or temporary tire flat-spotting.

Action: Should a customer express this concern, refer to the Service Instruction outlined below.

PARTS:

| Wheel weights | Locally sourced | Quantity: as required |

TOOLS:

Hunter 9700-series wheel balancing equipment

Hunter hub-to-wheel five-finger clamp

WARRANTY:

NOTE: Repair procedures are under constant review, and therefore times are subject to change; those quoted here must be taken as guidance only. Always refer to TOPIx to obtain the latest repair time.

NOTE: DDW requires the use of causal part numbers. Labor only claims must show the causal part number with a quantity of zero.

| DESCRIPTION | SRO | TIME (HOURS) | CONDITION CODE | CAUSAL PART |

|---|---|---|---|---|

| Road wheels – Vehicle set – Balance optimization and road test – XF, XK | 74.91.25 | 2.3 | D9 | C2P12002 |

| Road wheels – Vehicle set – Balance optimization and road test – F-TYPE, XJ | 74.91.25 | 2.2 | D9 | C2P12002 |

NOTE: Normal Warranty policies and procedures apply.

SERVICE INSTRUCTION:

- NOTE: Step 1 is part of the initial vehicle preparation process. No claim should be initiated if this step resolves the concern.

NOTE: Until flat-spots are removed, significant steering wheel vibration / shimmy may be present, even if the car has only stood overnight. A test drive is required to ensure temporary tire flat spots are removed. For longer term flat spots, a longer drive may be required. The test drive should be carried out on normal open roads to allow the highest speed that speed limits and road / traffic conditions allow.

If the vehicle has experienced a steering wheel vibration / shimmy during the Pre-Delivery Inspection (PDI) road test, refer to Technical Bulletin JTB00258NAS. If after performing the Service Instruction therein the concern is still evident, continue to step 3 below.

- If a customer complaint is being resolved, perform the following:

- Visually inspect the wheel and tire assemblies for damage, missing wheel weights, etc.

- Adjust the tire pressure to 29psi (2.0bar).

- Drive the vehicle for a minimum of 10 miles (15km) before attempting to assess steering wheel vibration / shimmy.

- If the level of steering wheel vibration is acceptable, no further action is required. Refer to the tire pressure label and adjust the tire pressures to the recommended cold tire pressures. If the levels of steering wheel vibration is unacceptable, continue to step 3.

- Immediately upon returning to the workshop, lift and support the vehicle to avoid inducing further tire flat spots(see TOPIx Workshop Manual, Section 100-02).

- Remove all four road wheel/tire assemblies.

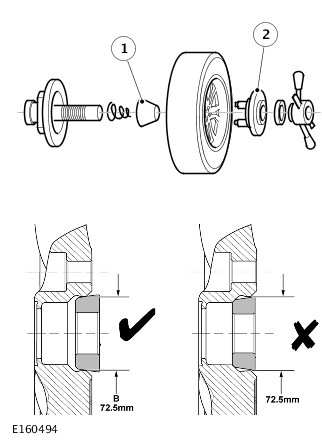

- NOTE: When using adhesive weights, use the attachment arm on the balancing equipment to ensure accurate weight positioning.

Mount each wheel/tire assembly (using the correct wheel-fitting attachment) to the balance machine and balance until the residual imbalance dynamic is minimized.

- Target is 0g (zero grams) on each plane; maximum is inner 5g / outer 5g.

- Use the ‘bulls-eye’ balancing mode to minimize residual imbalance.

- The maximum tire road force variations (RFV) for each wheel/tire assembly should be 60 Newton (6.1 kgf /

13.4 lbf) 1st harmonic RFV, 100 Newton (10.2 kgf / 22.5 lbf) peak-to-peak.

- If these levels cannot be achieved, perform the following:

- Remove the tire.

- Follow the match mounting procedure as detailed by the Hunter machine.

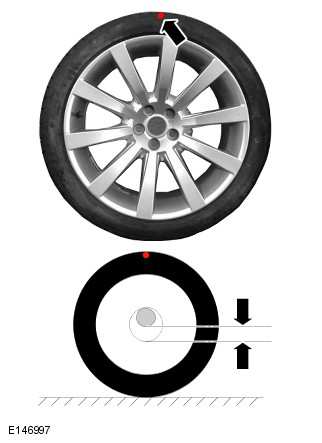

- Mark the high point of 1st harmonic RFV on the outer (and inner for future reference) sidewall of the tire.

- Install the lowest 1st harmonic RFV wheel/tire assemblies to the front axle.

- Print out the results of balance and force variation (before and after); attach to repair order.

- NOTE: If RFV equipment is not available and the tire has not been removed from the wheel and the RFV spot (red dot) is still visible, install wheel/tire assembly with red dot ‘up’.

Prior to tightening the wheel nuts, the marked high point of RFV must be installed to the vehicle with the RFV high point ‘up’.

- NOTE: Do not brace the wheel while tightening the nuts as this can disturb the match mounting.

Install the road wheel/tire assemblies on to the vehicle.

- Tighten wheel nuts to the specified torque (see TOPIx Workshop Manual, Section 204-04).

- Lower the vehicle.

- Drive the vehicle approximately 5 miles (7km) on normal roads and up to speeds of approximately 50 mph (80kph) to verify correction of steering wheel vibration / shimmy.

- Refer to the tire pressure label and adjust the tire pressures to the recommended cold inflation pressures.

Loading...

Loading...